Infinity Design Carbon Fibre Intake Kit – BMW M3

Description

INFINITY DESIGN was founded in 2014 operating from South Asia with the aim to provide the very best performance upgrades.... read moreDescription

INFINITY DESIGN was founded in 2014 operating from South Asia with the aim to provide the very best performance upgrades.

We design, engineer and build high end stainless steel and carbon fibre parts for performance cars.

We started with our world renowned S85 equal length headers which quickly gained popularity for it retaining the V10 sound track and adding serious power. This product has gone on to become the best there is. PRE PREG CARBON FIBER DESIGN & MANUFACTURE

In 2017 we started our carbon fibre intake development using high end Artec 3D scanners, 3D CAD software, CFD analysis and 3D print technology for prototyping. By the end of 2022 Infinity Design has become a well known choice for the ultimate in air intake systems for a number of BMW models. IN HOUSE DESIGNED AIR FILTRATION

We designed and use our own in house developed ISO9001 large surface area dual cone filters. The goal was to deliver performance parts which not just performed on the dyno but in the real world also along with unrivalled build quality and sophisticated sound tracks.

Our development process is an immersive experience that engages the emotions and intellect as well as the senses to create world class products.

OEM Intake Analysis

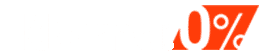

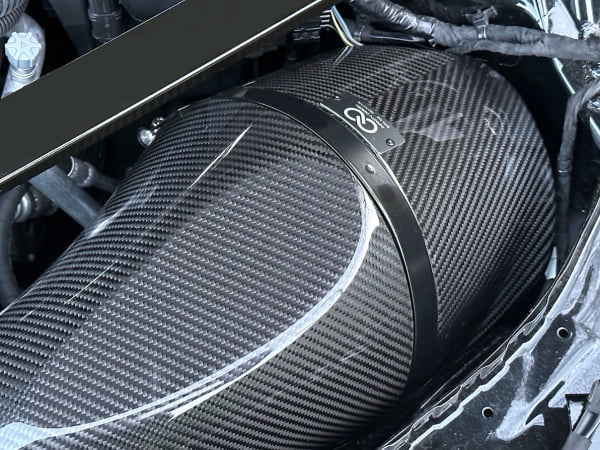

For the G Series M2, M3 and M4 we have taken full advantage of improving the intake system by not just replacing the intake but also the turbo inlets.

The flared out turbo inlets are significantly larger than the stock units and are designed to smooth out and increase air speed into the turbo impellers.

The turbo inlets are fed are by enlarged tapered intake tubes which take their air from our bespoke air filters which are housed in fully encapsulated air ducts / filter housings. We have spent a significant amount of time designing our air ducts and optimising them beyond the norm by having three cold air feeds.

The first feed comes from the frontal factory air inlet.

The second is a frontal air feed which are located in a region where we tested only ambient air reaches. The third and final feeds are the most interesting. They take from the gap between the chassis and wheel arch liners which face directly downwards.

This design strategy ensures the maximum amount of air at the lowest possible intake temperature.

The final result is a stunning under bonnet appearance matched with a more eager and smoother throttle response. More torque available faster and an intake sound which is sophisticated under load.

Additional information